Secondary Jaw Crusher Jaw Crusher

Primary Crusher vs Secondary Crusher: Understanding Their

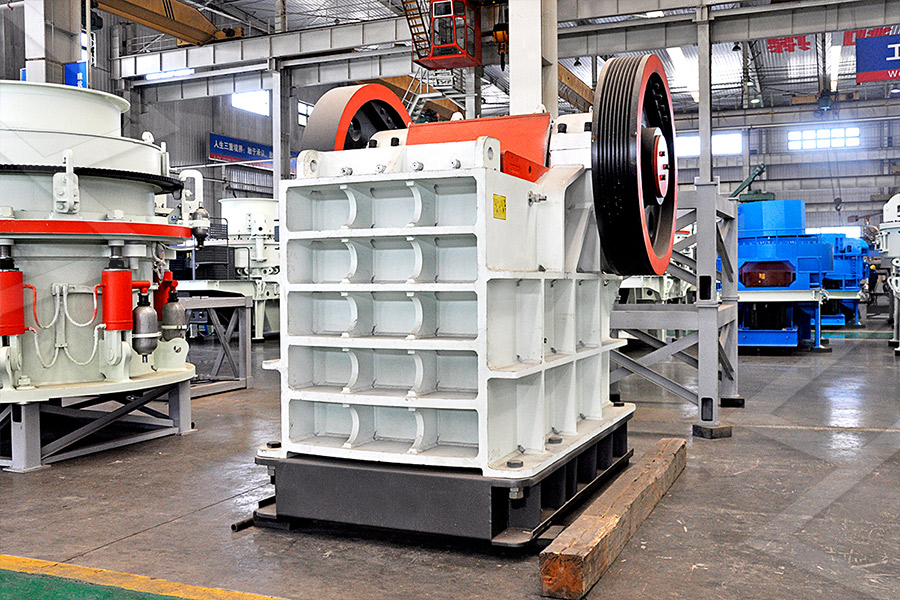

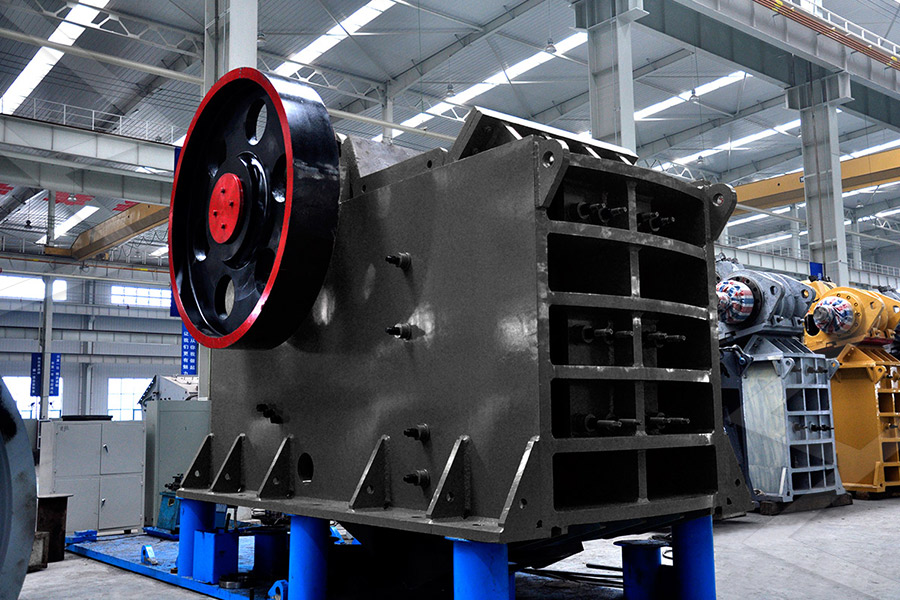

2023年2月28日 — The primary crusher is usually a jaw crusher or a gyratory crusher, which operates by compressing the material between two surfaces The jaw crusher works by In jaw crushers, the material is fed into the crushing chamber and is crushed The Complete Guide to Pri6 天之前 — Hanlinsky SJ Series jaw crushers are mainly used for coarse crushing and medium crushing for mining, building materials and infrastructure construction In most Sj Series Jaw Crushers for Primary or Secondary Crushing Jaw Crusher Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etcjaw crusher 百度百科

The Complete Guide to Primary Crushing,

2023年2月28日 — In jaw crushers, the material is fed into the crushing chamber and is crushed between a fixed jaw and a movable jaw Gyratory crushers work by crushing materials between a mantle and a concave, 2013年5月20日 — JCE series Jaw Crusher is ideally suitable for primary and secondary crushing and has already become the highend product of Jaw Crusher This machine JCE系列欧版颚式破碎机 JCE Series Jaw Crusher SKJ 2017年5月1日 — This study has attempted to develop a fundamental model including performance aspects of the jaw crusher for both potential future adoption in simulations A fundamental model of an industrialscale jaw crusher2020年4月1日 — Our jaw crushers are of the singletoggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle SANDVIK JAW CRUSHER SERIES Sandvik Mining and

A fundamental model of an industrialscale jaw crusher

2017年5月1日 — In a jaw crusher, the material is crushed between two plates: a static plate and a moving plate Compression is applied by the moving plate, and the material 2018年6月1日 — This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road Concrete aggregates properties crushed by jaw and impact secondary 2024年8月20日 — It is well known that in the production line of crushing, sand making and ore dressing, jaw crusher is used for coarse crushing as a primary crushing equipment (fine Jaw Crusher Basics in 3 MinutesSBM Industrial Technology 2024年9月20日 — Jaw crusher is suitable for crushing various soft and hard materials with compressive strength between 300350Mpa The models and specifications of ZENITH jaw crushers are all complete There are 7 Differences Between Jaw Crusher and Impact

3260 Portable Jaw Eagle Crusher

1 天前 — The Eagle 3260 Portable Jaw Crusher is designed to crush reinforced slab concrete with ease, reducing material prep time for processing 180025Eagle (2532453) DEALER LOCATOR; Blog; The Eagle 3242 portable jaw crusher provides highstrength construction without unnecessary weight, ideal for portable and skidmounted applications 180025Eagle (2532453) DEALER LOCATOR; Blog; Eagle 3242 Jaw Crusher2023年2月21日 — The hydraulic jaw crusher is ideal for crushing hard and abrasive materials, and it is commonly used in mining, metallurgy, building materials, and chemical industries One of the advantages of a hydraulic jaw crusher is its ability to adjust the discharge opening easily, allowing for a wider range of output sizesThe Ultimate Guide to Jaw Crushing Machines: Types2024年2月18日 — PE Jaw Crusher Primary Crusher The JOYAL Jaw Crusher is widely used in mining, building materials, chemical industry, metallurgy and so on The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPaJoyalJaw Crusher,Jaw Crusher For Sale,Jaw Crusher

Jaw Crusher Crushing Plant Hard Rock Mining Equipment

3 天之前 — DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPaDOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration 2013年3月17日 — 7 211 Tipe Stone Crusher Beberapa macam peralatan pemecah batu (stone crusher) meliputi : 1 Primary Crusher, biasanya menggunakan tipe crusher: a Jaw crusher (pemecah tipe rahang) Jaw crusher digunakan BAB II TINJAUAN PUSTAKA 21 Mesin Pemecah Batu 2024年9月26日 — The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42” x 20’ (1067 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machine Learn More about CRJ3042; MJ42 The MJ42 features the rugged JW42 Jaw Crusher for high production applicationsCedarapids JW42 Jaw Crusher Terex MPSWe call the machine that performs the CRUSHING process a CRUSHING MACHINE or CRUSHER MEKA Size Reduction Machines WHAT IS A JAW CRUSHER? / JAW CRUSHER This is a type of crusher that is widely used in the primary and secondary crushing processes It is usually preferred for the crushing of large blocks of hard and WHAT IS A JAW CRUSHER? MEKA

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

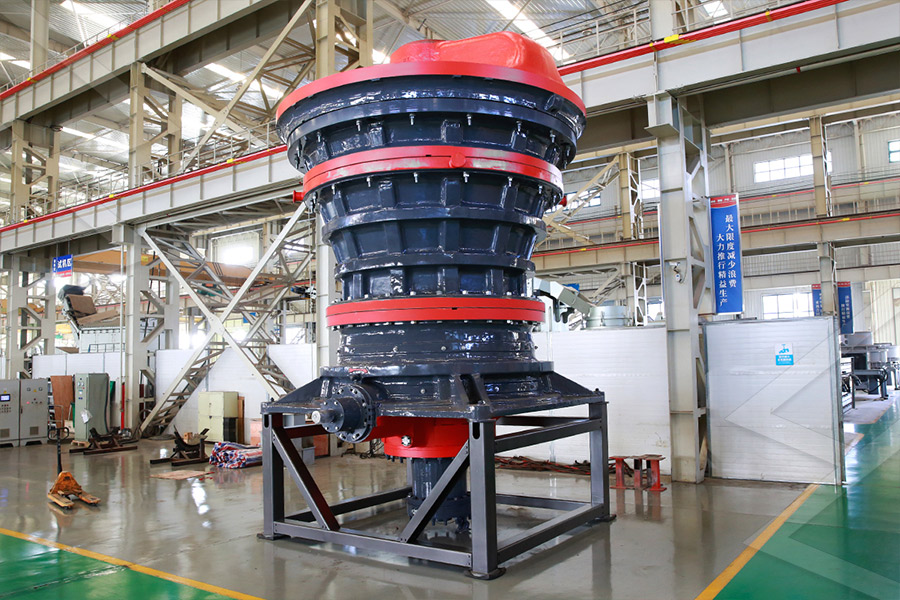

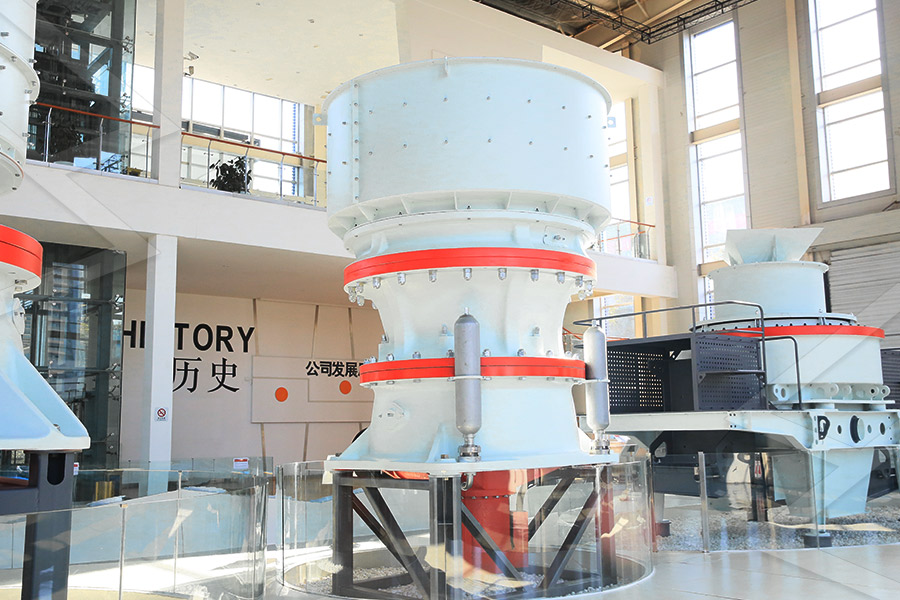

2023年5月27日 — Discharging size: The Jaw crusher is normally used for primary crushing which will give you a big crushing capacity and the output size is bigger but suitable for secondary crushing While cone crusher is for secondary and tertiary crushing stages, thus having a smaller discharging size2024年7月17日 — Jaw Crusher Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses When the two jaw plates come together, the material is crushed; when the plates move apart, material smaller than the discharge opening is released from the bottom The crushing action is Types of Crushers: Choosing the Right One for Each StageOften smaller and more expensive than a jaw crusher, gyratory crushers are suitable for larger amounts of materials when a more uniform shape is desired Parts diagram of a gyratory crusher Secondary crushing equipment After materials go though their first round of crushing, they are fed into a secondary crusher to be broken down furtherTypes of Crushers: What You Need to Know HUATAO GROUPManufacturer of Secondary Jaw Crusher 30 Manufacturer of Secondary Jaw Crusher 30 Deepa Machinery Manufacturers Private Limited Coimbatore Industrial Estate, Coimbatore, Tamil Nadu GST No Secondary Jaw Crusher 30"x10" (750x250mm)

Nordberg® C150™ jaw crusher Metso

Nordberg® C150™ jaw crusher is an effective jaw crusher in the 50ton (112 000 lbs) weight class It has been developed for the most demanding largescale mining and quarrying applications Crusher’s feed opening with long steep crushing cavity allows large coarse feed material up to onemeter (40”) size2017年6月30日 — A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER Sandvik C12 jaw crusher Feed opening 1,200 x 750 mm (47 x 29 in) Max feed size 650 mm (26 in) Capacity 450 mtph (496 stph) QJ341+ Jaw crusher Tracked jaw crushers UJ440i Jaw crusher Equipment Sandvik CJ412 jaw crusher Feed opening 1200 x 830 mm (47 x 33 in) Max feed size 750 mm (30 in)Mobile Crushers and Screens Sandvik mobile crushing SRP2024年9月26日 — Measurement of the crusher's closed side setting varies depending on the jaw profile that is being used and has an impact on the crusher's capacity and product gradation The following factors will enhance crusher capacity and performance: 1 Proper selection of the jaws 2 Proper feed gradation 3 Controlled feed rate 4Pex Series Fineness Jaw Crusher Mining Machine Pex300X1300

Jaw Crusher with “Multi Jaws” for Fine Crushing

2015年12月25日 — The Bakstad’s Patented Multiple Jaws, is a Jaw Crusher that represents the first real advance made in increasing the crushing range of jaw crushers since their introduction This Is the only crusher designed to give you a primary and two secondary crushers in one unit Crushers of the jaw principle type have conclusively demonstrated For crushing middle hard to hard and abrasive materials in primary and secondary crushing applications for low and high capacities Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plateSingle Toggle Jaw Crusher thyssenkrupp Polysius2020年3月19日 — Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept all material sizes Any material fed to the crusher must be presized for that particular crusher (usually 200mm or less)Selecting the right crusher for your operations QuarryThrough independent research and development, we innovated a series of Secondary Fine Rock Stone Jaw Crusher Pex300*1300 (PE300X1300) with independent intellectual property rights Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported Secondary Fine Rock Stone Jaw Crusher Pex300*1300

Jaw Crusher, Jaw Crusher Manufacturer, Jaw Crusher for Sale

4 天之前 — PE Series Jaw Crusher Based on years' experience and technology development, Zenith jaw crusher series are of 6 different models, which can meet most crushing requirements in primary and secondary crushing2024年2月20日 — Jaw Crusher: Primary: Gold, Copper, Limestone: Up to 1200mm (48 inches) 150mm300mm (612 inches) High durability, suitable for hard materials: Impact Crusher: Secondary: Limestone, Asphalt, What's the Difference: Impact Crusher vs Jaw 2023年6月29日 — Both jaw crusher and roll crusher are simple structure and crush hard material by extrusion forceJaw crushers are mainly used for coarse crushing and medium crushing processes, and roller crushers are fine crushing machines Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials Jaw Crusher VS Roller Crusher Baichy2020年7月10日 — The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on the variety of output sizes needing produced excavated, or reclaimed and process it through an impactor, jaw, or gyratory crusher What Is Primary, Secondary, and Tertiary Crushing Eagle Crusher

Vibrating Screen and Stone Crusher Manufacturer CPC

Stone Crusher 2406 MTH Series Secondary Jaw Crusher Stone Crusher 2166 AH Series Jaw Crusher Single Toggle Jaw Crusher VS 1454 Wire Mesh Design Vibrating Screen 4432 HiPro Series Primary Jaw Crusher Call 75% Response Rate Send Email About C PC E quipments P PE600times;900 jaw crusher is used in the first process of coarse and medium crushing various minerals and rocks The advantages of high efficiency, strong crushing capacity and low investment cost make jaw crusher popular in mining, metallurgy, and other industries Specifications Technical Data Jaw crusher PE600times;900 Henan LIMING Heavy6 天之前 — Available in a variety of sizes and configurations, the HydraJaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver highcapacity crushing and reliable performance for increased operational productivity and profitability mining and recycling in both primary and secondary applicationsJaw Crushers AstecCrushers Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jawcrusher Construction Jaw crushers are heavyduty machines and hence must be robustly constructed The main frame is often made from cast iron or steel, connected with tiebolts It is commonly made in sections so that it can be Jaw Crusher an overview ScienceDirect Topics

What Are Jaw Crushers and How Do They Work? Oreflow

The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down2019年1月1日 — The chemical composition of both products is very similar The content of silica is lower in the fine fractions, while the content of CaO + LOI is higher, indicating a preferential concentration of cement paste in the finer fraction and natural aggregates in the coarser fractionsThe results between the jaw and impact crusher differ only slightly, Concrete aggregates properties crushed by jaw and impact secondary Find out all of the information about the Henan Hongxing Mining Machinery CO,LTD product: jaw crusher PE series Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point Jaw crusher PE series Henan Hongxing For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate Jaw Crusher Explained saVRee

Universal Jaw Crushers McLanahan

Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first overhead eccentric jaw crushers Since that time, this robust design has continued to be the basis of the Universal Jaw Crusher design In addition to the standard jaw crusher design, McLanahan also produces the HSeries, which features adjustonthefly capabilities2023年2月23日 — Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries These machines are designed to crush large rocks and ores into smaller pieces for further processing A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the Understanding Jaw Crusher Parts and Their Functions AGICOTERMINATOR Jaw Crusher Model JCT#1AL Automatic Lubrication, capacity 5" X 7" Unit, equipped with one set of smooth or serrated jaws (alloy 1 or 2), 208/220/440/575 volt, 3 phase, 60 cycles, 5 HP motor,TM Engineering Terminator Jaw Crusher Secondary Jaw Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavyduty double roll Jaw Crushers McLanahan

PE250x1200 fine jaw crusher Sandman Crusher

PE250x1200 fine jaw crusher,PE250x1200 fine jaw crusher feeding size is 210 mm, the output size is 2590 mm, capacity is 2070 t/h The final size can be 030mm also can be used as secondary crushing, portable type crusher, and stationary type crushing plant This crusher can be used for crushing all kinds of ore, waste rock, construction 2024年8月20日 — The jaw crusher has a simple structure, is easy to manufacture, reliable in operation, and convenient to use and maintain The fineness of the jaw crusher can be varied from 10mm to 105mm, and it can be adjusted according to customers' needs Jaw crusher prices vary according to model and production capacityJaw Crusher Basics in 3 MinutesSBM Industrial Technology 2024年3月20日 — Cone crushers, on the other hand, are more often used in the secondary and tertiary crushing stages After the jaw crusher has done the primary crushing, the material gets fed into a cone crusher to be made even smaller Sometimes, several cone crushers might be used one after the other to get the product to the desired size and shapeUltimate Comparison: Jaw Crusher vs Cone Crusher JXSC2024年9月20日 — Jaw crusher is suitable for crushing various soft and hard materials with compressive strength between 300350Mpa The models and specifications of ZENITH jaw crushers are all complete There are 7 Differences Between Jaw Crusher and Impact

3260 Portable Jaw Eagle Crusher

1 天前 — The Eagle 3260 Portable Jaw Crusher is designed to crush reinforced slab concrete with ease, reducing material prep time for processing 180025Eagle (2532453) DEALER LOCATOR; Blog; The Eagle 3242 portable jaw crusher provides highstrength construction without unnecessary weight, ideal for portable and skidmounted applications 180025Eagle (2532453) DEALER LOCATOR; Blog; Eagle 3242 Jaw Crusher2023年2月21日 — The hydraulic jaw crusher is ideal for crushing hard and abrasive materials, and it is commonly used in mining, metallurgy, building materials, and chemical industries One of the advantages of a hydraulic jaw crusher is its ability to adjust the discharge opening easily, allowing for a wider range of output sizesThe Ultimate Guide to Jaw Crushing Machines: Types2024年2月18日 — PE Jaw Crusher Primary Crusher The JOYAL Jaw Crusher is widely used in mining, building materials, chemical industry, metallurgy and so on The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPaJoyalJaw Crusher,Jaw Crusher For Sale,Jaw Crusher

Jaw Crusher Crushing Plant Hard Rock Mining Equipment

3 天之前 — DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPaDOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration 2013年3月17日 — 7 211 Tipe Stone Crusher Beberapa macam peralatan pemecah batu (stone crusher) meliputi : 1 Primary Crusher, biasanya menggunakan tipe crusher: a Jaw crusher (pemecah tipe rahang) Jaw crusher digunakan BAB II TINJAUAN PUSTAKA 21 Mesin Pemecah Batu 2024年9月26日 — The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42” x 20’ (1067 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machine Learn More about CRJ3042; MJ42 The MJ42 features the rugged JW42 Jaw Crusher for high production applicationsCedarapids JW42 Jaw Crusher Terex MPSWe call the machine that performs the CRUSHING process a CRUSHING MACHINE or CRUSHER MEKA Size Reduction Machines WHAT IS A JAW CRUSHER? / JAW CRUSHER This is a type of crusher that is widely used in the primary and secondary crushing processes It is usually preferred for the crushing of large blocks of hard and WHAT IS A JAW CRUSHER? MEKA

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023年5月27日 — Discharging size: The Jaw crusher is normally used for primary crushing which will give you a big crushing capacity and the output size is bigger but suitable for secondary crushing While cone crusher is for secondary and tertiary crushing stages, thus having a smaller discharging size