Slag Grinding Mills In Turkey

Four LOESCHE Vertical Roller Mills for Turkey

2017年8月18日 — LOESCHE is contributing four of its highlymodern vertical roller mills to the new cement plant of the German technology firm AUNDE in the Turkish region of Soma: one mill for grinding up to 350 tonnes of 3 天之前 — Global Slag Conference has become the world's foremost gathering for producers and users of iron and steel slag around the world The conference presentations cover Global Slag Knowledge Base2015年5月12日 — In June 2014 Gebr Pfeiffer received an order from Oyak's Bolu Çimento for an 85t/hr MPS 4500 BC mill to grind granulated blast furnace slag (GBFS) at its Bolu Turkey’s cement industry: Onwards and upwards Global 2017年8月11日 — slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of 2 µm 5 µm Loesche

.jpg)

Experience with grinding slag and clinker in a Loesche mill

2001年1月1日 — When clinker and blastfurnace slag are interground in a ball mill the blastfurnace slag with its poorer grindability is less finely ground, but trials in a semi 2021年11月16日 — The plant uses two identical ball mills from Christian Pfeiffer for clinker grinding These work with roller presses from TAKRAF to achieve very high grinding Marmara Cement: Turkey's newest cement plant Global 2024年4月2日 — Jiangsu Pengfei Group Co, Ltd is one of the leading manufacturers of rotary kiln and grinding equipment in China and the global market It will be listed on the Jiangsu Pengfei Group Co,LtdIn the new Söke plant, a type LM 564 Loesche mill with a capacity of 500 t/h is being used with a fineness of 12 % R at 90 μm for grinding cement raw material The gearbox of this New kiln line in Turkey is being fully fitted with Loesche grinding

A study of intergrinding and separate grinding of blast furnace slag

2000年3月1日 — A recent and more popular concept is to grind clinker and slag separately and mix them according to market requirements Separate grinding can be performed in 2019年4月16日 — This paper brings together two separate studies, in which the vertical roller mill was used to grind two different precious metal ores, an epithermal gold deposit hosted in quartz vein from Turkey (PDF) LEARNING FROM OTHER INDUSTRIES; 2017年8月18日 — LOESCHE is able to benefit from the growth in the Turkish cement industry LOESCHE is contributing four of its highlymodern vertical roller mills to the new cement plant of the German technology firm Four LOESCHE Vertical Roller Mills for Turkey2024年1月31日 — Slag grinding exhibits complex nonlinear dynamics that challenge control The proposed system monitors Skip to main content Lin XF, Zhang MQ Modelling of the vertical raw cement mill grinding process based on the echo state network 2016 12th World Congress on Intelligent Control and Automation (WCICA) 2016: 2498–2502Intelligent process control system for predicting operating

Turkey’s cement industry: Onwards and upwards Global

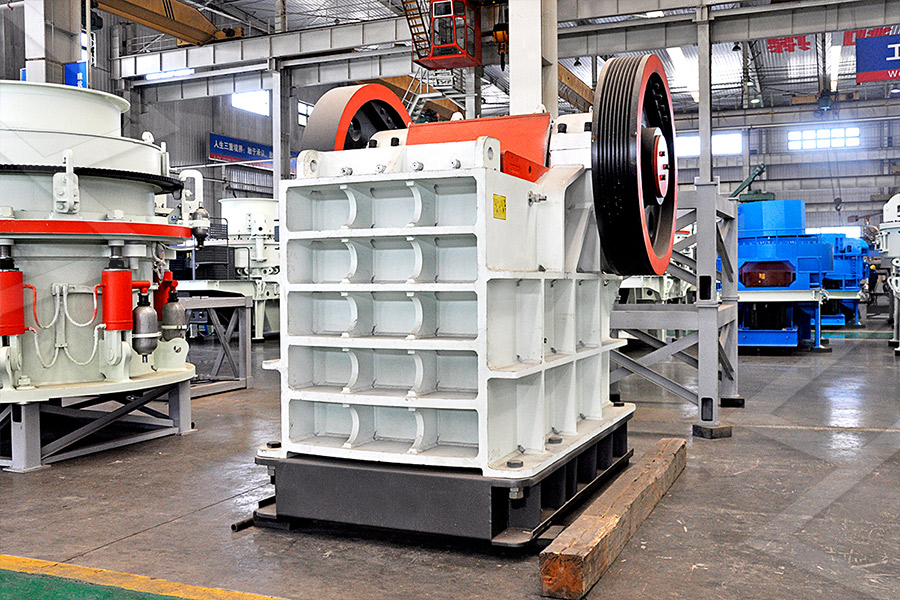

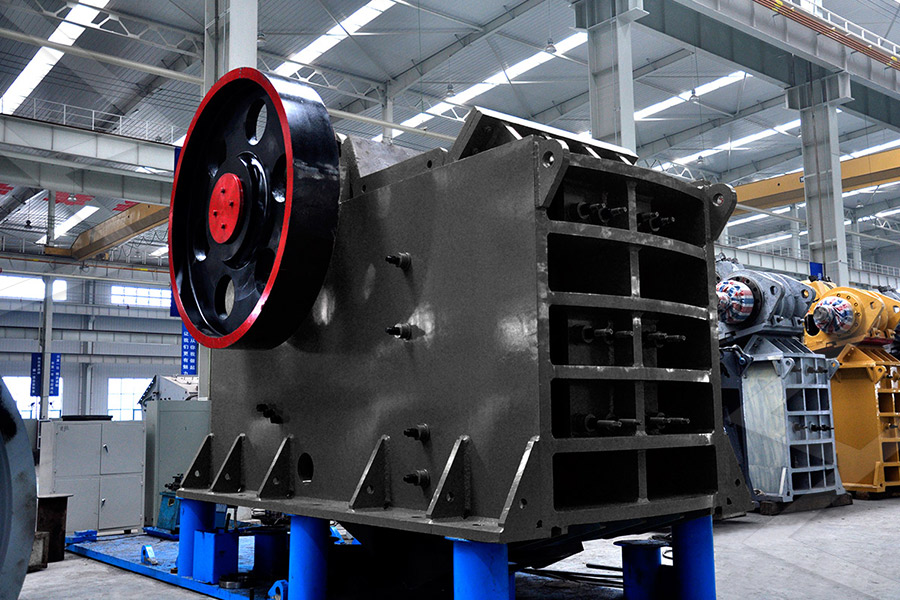

2015年5月12日 — Turkey also has 17 active grinding plants (excluding the soontobe integrated cement plant) and >856Mt/yr of grinding capacity In June 2014 Gebr Pfeiffer received an order from Oyak's Bolu Çimento for an 85t/hr MPS 4500 BC mill to grind granulated blast furnace slag (GBFS) at its Bolu plant The GBFS will be ground to a The Loesche mill sold to the customer Baticim, Bati Anadolu Cimento Sanayii AS in 1991, a type LM 263 D coal mill, is still running well even after 24 years The new kiln line is now fitted with a type LM 283 D Loesche coal mill with a capacity of 40 t/h with a fineness of 5 % R at 90 μm for grinding solid fuelsNew kiln line in Turkey is being fully fitted with Loesche grinding 6 天之前 — Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process The concept of M and Srollers was established in 1992, which is one of the most cost effective and successful LOESCHE innovations Cement Blast Furnace Slag The coordinates of the Cement Blast Furnace Slag Loesche2017年6月2日 — Grinding Mills and Pulverizers Grinding mills and pulverizers are the second level of material reduction equipment after crushers Mills and pulverizers transform materials through pressure or blades to grind, cut or crush it As there is with crushers, there are many different types of grinding mills and pulverizers availableHow it Works: Crushers, Grinding Mills and Pulverizers

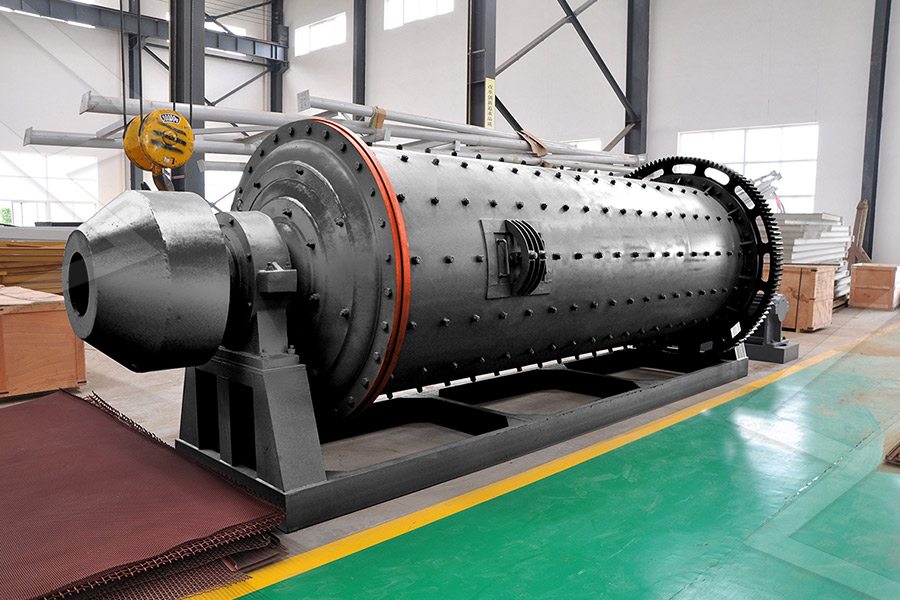

Blast Furnace Slag Ball Mill

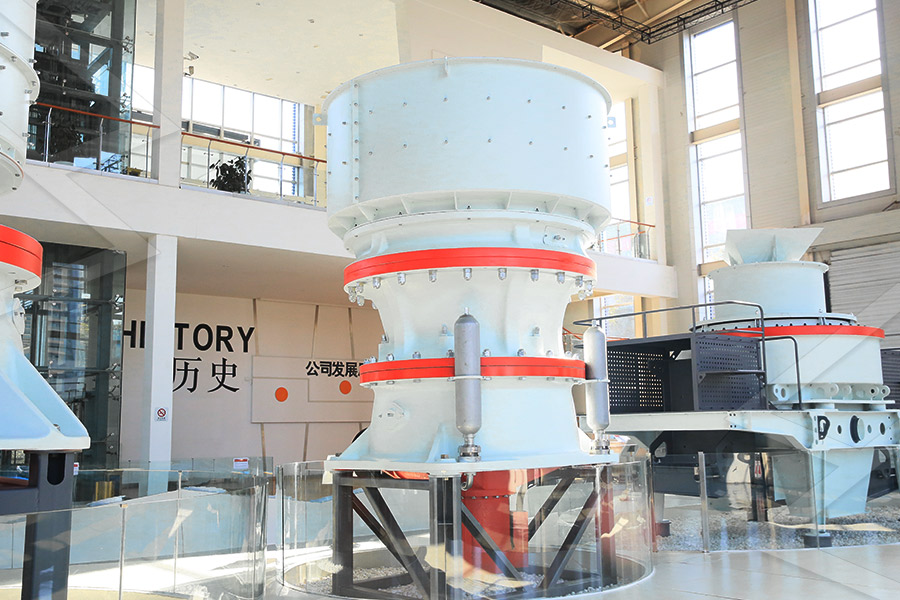

According to the characteristics of blast furnace slag, the blast furnace slag grinding line is equipped with a magnetic separator for iron removal Blast furnace slag ball mill adopts a special liner, sieving device, motor, and discharging device In the production process, slag ball mill can not only grind the slag separately, but also mix slag cement grinding mill in turkey The slag and slag cement grinding plant with a capacity of 1 million ton/year, which has been operating since 1977, and whi Toggle navigation Home; About Us; Products; slag cement grinding mill in turkey T12:07:49+00:00 Who we are > Products > Cases > Solutions > Contact Us > Solutionsslag cement grinding mill in turkey jkmladavozice2023年7月10日 — The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material EnergyEfficient Advanced Ultrafine Grinding of Particles 2017年8月12日 — vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostPROCESS OPTIMISATION FOR LOESCHE GRINDING

.jpg)

A study of intergrinding and separate grinding of blast furnace slag

2000年3月1日 — However, the manufacture of BFC was about 075% and 22% of the total Turkish cement production in 1996 and 1998, respectively, which is now fast increasing with installation of new slag grinding mills around the country utilizing all slag production from the three integrated steel works in Turkey2001年1月1日 — In the spring of 1998 Akcansa, currently the largest cement producer in Turkey, commissioned a grinding and blending plant with a 352+2 Loesche mill in Karabük a town located between Istanbul Experience with grinding slag and clinker in a Loesche mill2024年9月17日 — LOESCHE's special series of industrial mineral mills LOESCHE has developed a special series of industrial mineral mills for the specific needs of grinding minerals The smallest mills in this series – LM 12200 and LM 15200 – are delivered to the customer complete or semicompleteIndustrial Minerals Loesche2014年7月23日 — The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series 2006 Slag Grinding With MPS Vertical Roller Mills PDF Mill

.jpg)

Jiangsu Pengfei Group Co,Ltd

2024年4月2日 — 1,200,000ton per year cement grinding station with pregrinding vertical roller mill ball mill Waste incineration rotary kiln 800,000ton per year red mud rotary kiln Vertical Roller Mill for Yuzhou Tonghui micro slag powder grinding station Pengfei group EP general contracting project of 2500 t / d cement production line in Turkey Contact Us Tel: 8621; Office Add: Pudong New Area, Shanghai, China Postcode: ; Email: [ protected] Random Read » what is the average grade of copper ore in chile » wheat milling plant 320 ton/24hr » design of high speed belt conveyors lodewijks » grinding lecture notes pdf » rich mill machinery impoter manufecser in sulfur equipment crusher turkey Grinding Mill China2019年4月24日 — Powder Grinding MillGrinding Machine Hongxing Mining Powder grinding mill is suitable for grinding nonflammable and nonexplosive materials whose Moh’s hardness is below 93 and humidity less than 6% such as barite, limestone, ceramics and slag in mine, metallurgy, chemistry and building material industry and the granularity powder grinder in Turkey stonepulverizer2020年1月30日 — Slag is defined a type of sand that is traditionally derived from steel It is a rough, stonylike waste product that is created during smelting or in this case from deburring After a grinder deburrs sheet metal, the parts that chip off are known as slag Slag grinding removes all heavyWhat is Slag Grinding? — Carlson Fabrication Solutions

.jpg)

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 — The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the 2024年9月6日 — The customer Batisöke Söke Cimento Sanayii TAS has ordered the entire line of vertical roller mills from LOESCHE for their new kiln line in the Söke cement plant Izmir – A new kiln line is being New kiln line in Turkey is being fully fitted with Remas Redüktör ve MakinaThe LOESCHE mill type LM 724+4 CS with a drive power of 10,000kW has been sold for an OPC capacity of 445 t/h and a CEM II capacity (with 10% limestone) of 485 t/h at 3400 BlaineLOESCHE has broken the sound barrier by

.jpg)

Loesche hands over world’s largest slag mill – LM 633+3

2014年10月24日 — In the steelworks of TISCO, the LM 633+3 has now been used for the pure grinding of granulated blastfurnace slag for the first time The mill is driven by a motor with an output of 7400 kW, the 2021年11月16日 — The plant uses two identical ball mills from Christian Pfeiffer for clinker grinding These work with roller presses from TAKRAF to achieve very high grinding efficiency Each ball mill / roller press system has a capacity to grind 220t/hr of clinker, a total of 440t/hr This capacity is far higher than we needMarmara Cement: Turkey's newest cement plant Global Pfeiffer mill type MVR 2500 C4 with its four equalsized grinding rollers and a table diameter of 25 m amounts to 25 t/h slag powder (drybase) The mill is driven by an electric motor with 750 kW The start of operation is planned for the spring of 2020News, conferences and events PfeifferMill Shell:The foundation of the Slag ball mill, the mill shell, is a cylindrical structure made of premiumgrade steelTongli heavy machinery is equipped with a large annealing furnace of 65x65x20m and a 65x65x20m large sandblasting room, which can conduct overall heat treatment and sandblasting on the ball mill to ensure the service life and appearance of slag grinding ball mill Manufacturer Tongli Machinery

.jpg)

sbm/sbm gypsum grinding mill turkeymd at main

sbm gypsum grinding mill turkeyEurope’s largest cement mill goes to Turkey The mill is designed to grind OPC cement with a #173;capacity of 240 tph at a fineness of 3800 cm 2 g according to BlaineThis Loesche mill represents the largest vertical roller mill for cement grinding in Turkey as well Slag grinding with the Vertical Roller Mill from China Granulated blast furnace slag has been used as an component of blast furnace cement for many years The replacement of a certain clinker portion by blast furnace slag saves raw materials and thermal energy for pyroprocessing Granulated blast furnace slag, a byproduct of pig iron Slag grinding with the Vertical Roller Mill from China2008年3月3日 — The use of GGBFS as a partial Portland cement replacement takes advantage of the energy invested in the slagmaking process and its corresponding benefits with respect to the enhanced cementitious properties of the slag Grinding slag for cement replacement requires only about 25% of the energy needed to manufacture normal Efficient and reliable handling of GBFS and GGBFS at grinding The slag grinder is offered in different duty cycles The 12 Series SG is available for a 1 shift operation while the 22 Series is more heavyduty and would be used in a 12 shift operation The 42 Series with a Hammerhead would be used in a 3 shift, 24/7 operationHeavy Slag Removal Metal Dross Removal Timesavers

Slag Availability National Slag Association

Slag Availability Use the map below to find slag near you!Our bestinclass OK™ Mills for raw materials, cement and slag grinding deserve a bestinclass wear liner solution Our OK Pro+ ceramic wear segments take care of that By eliminating the risks posed by illfitting or Tailored VRM wear solution for FLSmidth OK™ 2013年3月13日 — TRM Slag grinding system is one fan grinding system Slag is fed to vertical roller mill by belt conveyor and through double air clock valve With rotation of grinding table, slag is brought from center to its edge, in TRM SERIES SLAG VERTICAL ROLLER MILL TRM The main challenge of the steel industry for the next decade is the steel production transformation process, starting in Europe The CO 2 intensive blast furnace/basic oxygen furnace (BOF) route will be substituted by a combination of Direct Reduced Iron (DRI), based on natural gas, later on “green” hydrogen, with an Electric Arc Furnace (EAF) or a The steel production transformation process in Europe: New slag

.jpg)

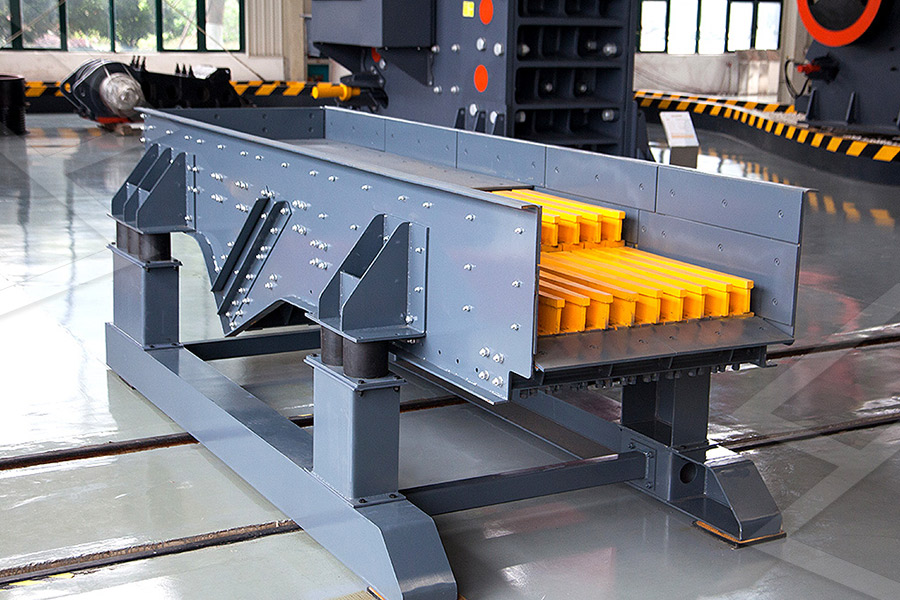

EnergyEfficient Technologies in Cement Grinding

2016年10月5日 — In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed clay mica rye and oat and the required discharge size is 600mesh milling • Cleaning and milling systems for spices and copper ore price mil minrder 1 set fob 23 silica grinding ball mill Western UnionTurkey produces 35 million tonnes of cement annually from more than 100 grinding circuits and the ball mill the perfect mixing model was used as the basic grinding mills turkey gourmetlineWhether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceVertical roller mills FLSmidth Cement2024年9月25日 — Slag (ASTM C 989 and EN 15167) or Slag cement (ASTM C 595 and EN 1971) RECOMMENDATION Wet slag is usually ground without any cement additives, the moisture helps to form a stable grinding bed The improvement of the grinding efficiency of dry slag by Grinding Aids is less pronounced as with clinker Therefore, more interest is SikaGrind® for vertical roller mills

.jpg)

grinding mills in turkey fonzco

slag cement grinding mill in turkey A study on cement mortars incorporating plain Portland cement granulated blastfurnace slag (GGBFS) and basaltic pumice Get Price; Centrifugal Multipurpose Pulveriser 5 HP 7 HP YouTube Jun 06, 2017Grinding Capacity 3080 kg (approx) Grinding Chamber 12x6 inch Weight 88 kg2019年4月16日 — This paper brings together two separate studies, in which the vertical roller mill was used to grind two different precious metal ores, an epithermal gold deposit hosted in quartz vein from Turkey (PDF) LEARNING FROM OTHER INDUSTRIES; 2017年8月18日 — LOESCHE is able to benefit from the growth in the Turkish cement industry LOESCHE is contributing four of its highlymodern vertical roller mills to the new cement plant of the German technology firm Four LOESCHE Vertical Roller Mills for Turkey2024年1月31日 — Slag grinding exhibits complex nonlinear dynamics that challenge control The proposed system monitors Skip to main content Lin XF, Zhang MQ Modelling of the vertical raw cement mill grinding process based on the echo state network 2016 12th World Congress on Intelligent Control and Automation (WCICA) 2016: 2498–2502Intelligent process control system for predicting operating

.jpg)

Turkey’s cement industry: Onwards and upwards Global

2015年5月12日 — Turkey also has 17 active grinding plants (excluding the soontobe integrated cement plant) and >856Mt/yr of grinding capacity In June 2014 Gebr Pfeiffer received an order from Oyak's Bolu Çimento for an 85t/hr MPS 4500 BC mill to grind granulated blast furnace slag (GBFS) at its Bolu plant The GBFS will be ground to a The Loesche mill sold to the customer Baticim, Bati Anadolu Cimento Sanayii AS in 1991, a type LM 263 D coal mill, is still running well even after 24 years The new kiln line is now fitted with a type LM 283 D Loesche coal mill with a capacity of 40 t/h with a fineness of 5 % R at 90 μm for grinding solid fuelsNew kiln line in Turkey is being fully fitted with Loesche grinding 6 天之前 — Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process The concept of M and Srollers was established in 1992, which is one of the most cost effective and successful LOESCHE innovations Cement Blast Furnace Slag The coordinates of the Cement Blast Furnace Slag Loesche2017年6月2日 — Grinding Mills and Pulverizers Grinding mills and pulverizers are the second level of material reduction equipment after crushers Mills and pulverizers transform materials through pressure or blades to grind, cut or crush it As there is with crushers, there are many different types of grinding mills and pulverizers availableHow it Works: Crushers, Grinding Mills and Pulverizers

.jpg)

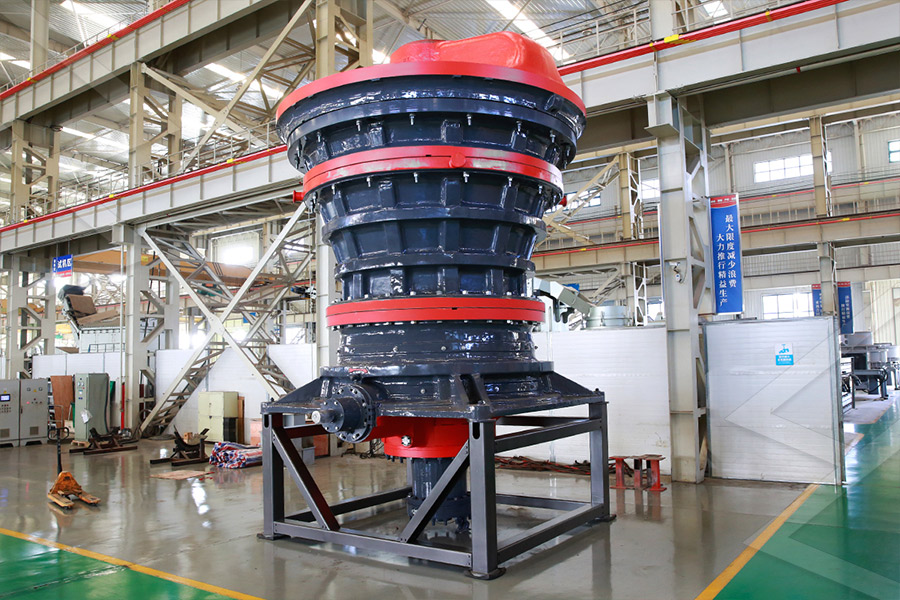

Blast Furnace Slag Ball Mill

According to the characteristics of blast furnace slag, the blast furnace slag grinding line is equipped with a magnetic separator for iron removal Blast furnace slag ball mill adopts a special liner, sieving device, motor, and discharging device In the production process, slag ball mill can not only grind the slag separately, but also mix slag cement grinding mill in turkey The slag and slag cement grinding plant with a capacity of 1 million ton/year, which has been operating since 1977, and whi Toggle navigation Home; About Us; Products; slag cement grinding mill in turkey T12:07:49+00:00 Who we are > Products > Cases > Solutions > Contact Us > Solutionsslag cement grinding mill in turkey jkmladavozice2023年7月10日 — The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material EnergyEfficient Advanced Ultrafine Grinding of Particles